Why do problems appear with aftermarket actuators on the Mercedes OM642 turbo?

Owners of Mercedes vehicles with the OM642 engine (3.0 V6 CDI) often face turbocharger failures when non-OEM (aftermarket) actuators are installed.

At first glance, the cheaper option may look attractive – but in practice it leads to serious consequences:

❌ Loss of engine power

❌ Communication errors

❌ Limp-mode activation

❌ Expensive failures and repairs

In this article we explain why aftermarket actuators for the Mercedes OM642 turbo do not function properly, which errors usually occur, and why the only reliable solution is – an OEM actuator (new or remanufactured & programmed according to factory standards).

The root of the problem – why aftermarket actuators fail

No factory-defined position maps

An actuator cannot simply be bolted onto the turbo – calibration using special equipment is required.

Manufacturing errors

During CAN programming, aftermarket actuators often fail to store new parameters → resulting in incorrect mapping and uncontrolled boost pressure.

Weak components

Cheaper electronics and mechanics cannot withstand real-world driving loads.

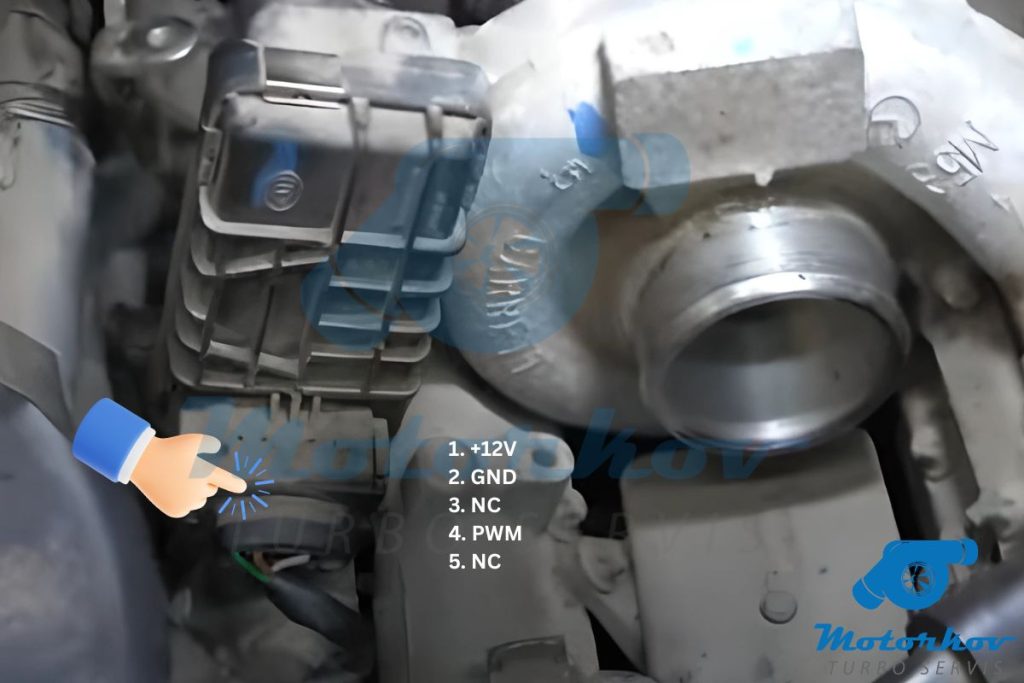

Insufficient precision with PWM signal

On the Mercedes OM642 turbo, the ECU controls VNT geometry exclusively via PWM signal.

Aftermarket actuators often lack the required precision → causing higher fuel consumption, lower performance, and limp-mode activation.

👉 Learn more about the principle of variable geometry in our blog: VNT Technology – Maximum Performance

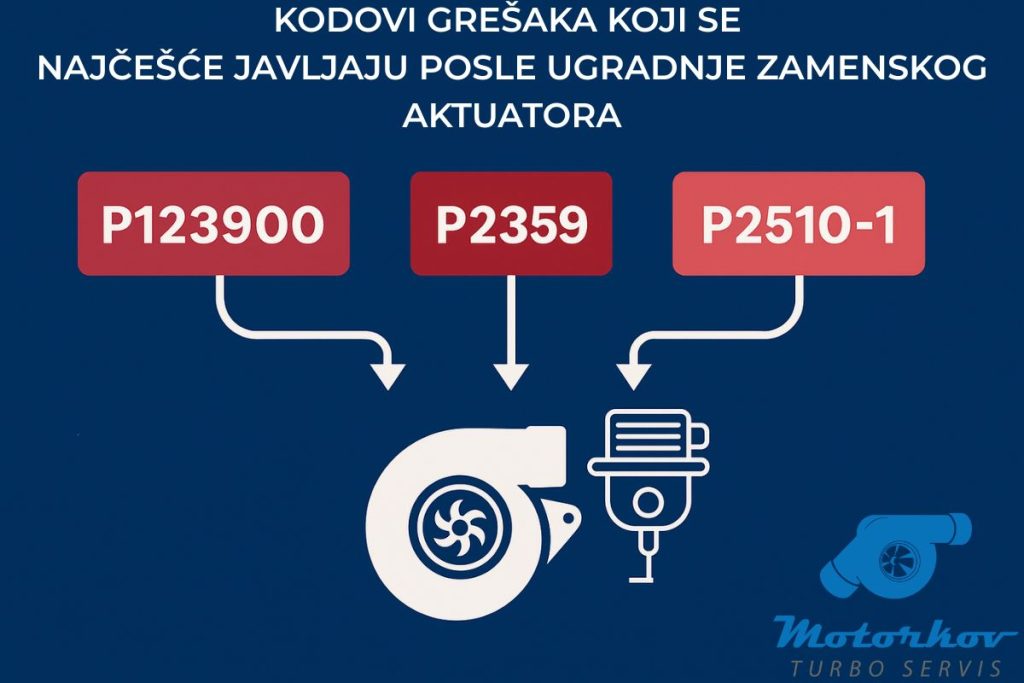

Common DTC error codes with Mercedes OM642 turbo actuators

P123900 – Turbocharger Actuator “A”

Positioning error of the VNT mechanism caused by a faulty actuator.

P2359 – Boost Pressure Too High

Actuator positions the vanes incorrectly → turbo produces excess boost, ECU detects the risk and reduces performance.

P2510-1 – ECM Power Relay Malfunction

Indicates faulty actuator behavior. With aftermarket actuators, this appears due to failed CAN programming.

👉 If these codes appear on your Mercedes diagnostics, there is a high probability the cause is an aftermarket turbo actuator.

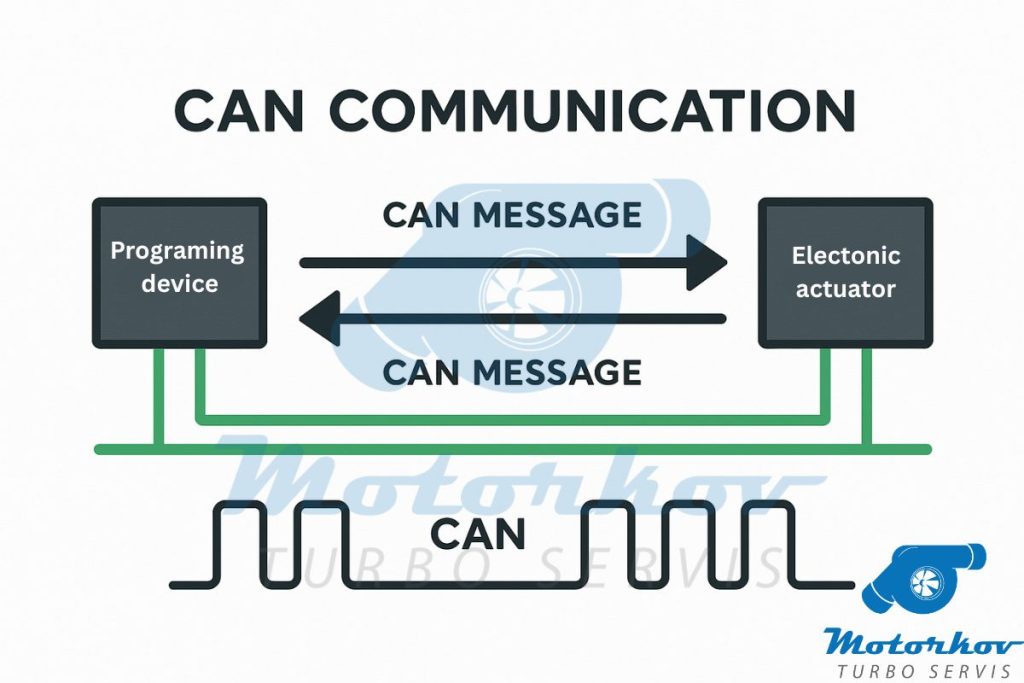

CAN communication during programming (OM642 actuators)

- Aftermarket actuator → loses CAN packets due to poor components → EPROM stores incomplete data → incorrect mapping.

- CAN (Controller Area Network) is used only during REA actuator programming.

- OEM actuator → receives and processes data correctly.

PWM signal during operation

During driving, the ECU controls VNT positioning exclusively via PWM signal.

- OEM actuator → responds accurately and consistently.

- Aftermarket actuator → delays and oscillations → loss of power and higher fuel consumption.

👉 The three wires on the actuator harness confirm that PWM communication is used on the Mercedes OM642.

Actuator part numbers on Mercedes OM642 turbochargers

For the Mercedes OM642 (3.0 V6 CDI), electronic actuators differ by serial part numbers on the cover and by G-numbers. These codes are critical when replacing or repairing the turbo actuator.

Common part numbers (cover):

- 6NW 008 412

- 6NW 009 420

- 6NW 009 660

- 6NW 009 543

G-numbers (technical codes):

- G-219

- G-277

- G-001

- G-13

🔧 Workshop note: Regardless of the code, the working principle is the same – CAN is used only during programming, while during operation the ECU communicates with the actuator via PWM.

❗ The problem arises with aftermarket actuators – they do not contain factory-defined position maps, leading to unstable turbo operation and ECU error codes (P123900, P2359, P2510-1).

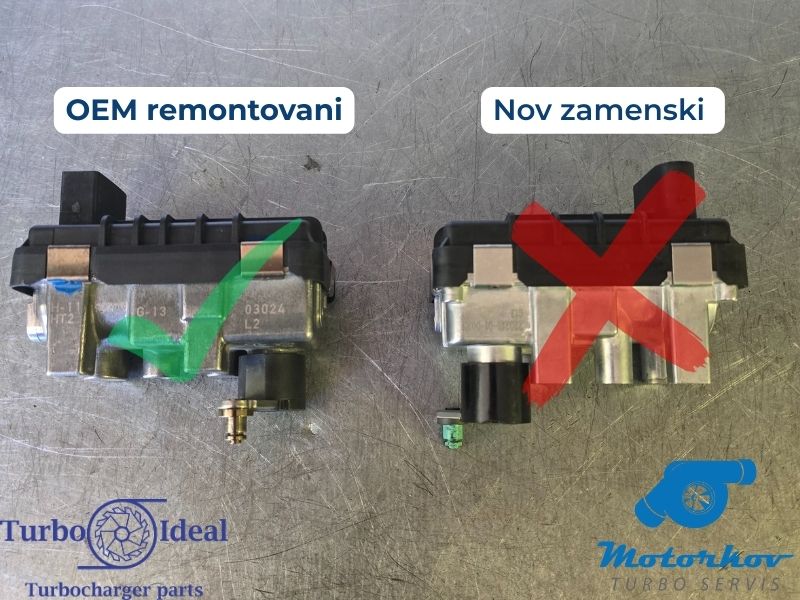

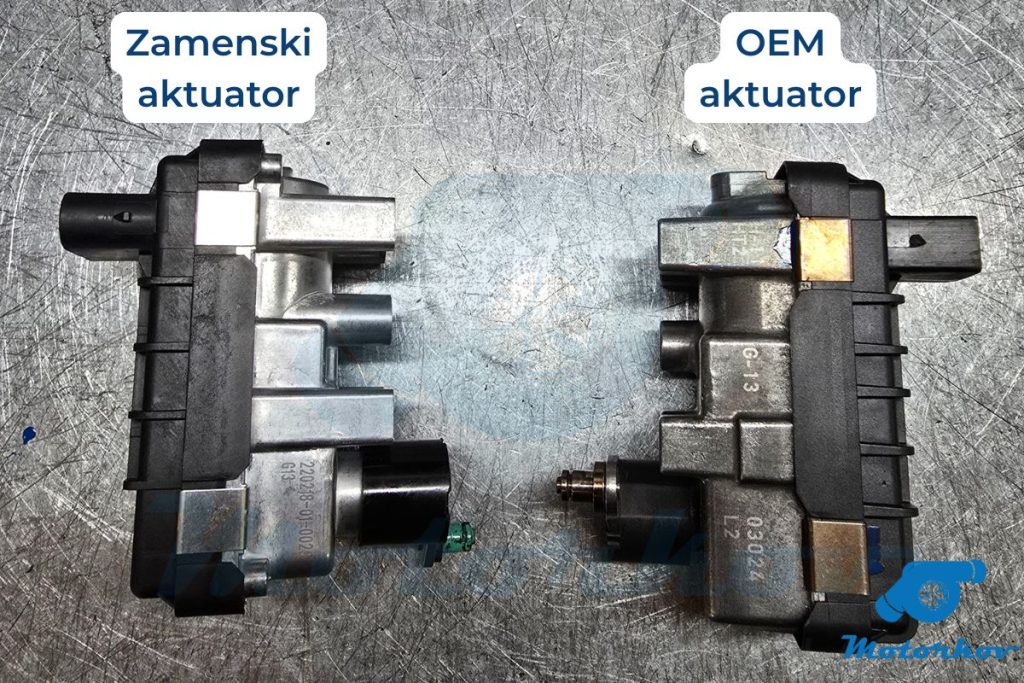

OEM vs Aftermarket Actuator – examples

- OEM actuator 6NW 009 420 → factory remanufactured and correctly programmed.

- OEM actuator G-219 → ensures reliable turbo performance.

- Aftermarket actuator 6NW 009 660 → example of unstable PWM signal and turbo failure.

👉 Test your knowledge about turbochargers in our 👉 Expert Turbo Quiz.

Motorkov repair process – with video

In our Motorkov workshop the process looks like this:

- Remanufacture the original OEM actuator – replacing all faulty electronic and mechanical parts.

- Program end-positions via CAN – restoring factory-defined position maps.

- Turbo calibration on the test bench – ensuring flow and boost meet OEM standards.

🎥 Watch our detailed video about actuator repair and programming:

👉 Electronic actuator repair – Turbo Ideal (YouTube)

✅ Result: Your Mercedes OM642 turbocharger works like new – full performance, no errors.

Conclusion – why OEM is the only correct solution

- ✅ Only an OEM actuator (new or properly remanufactured & programmed) restores the turbo to factory condition.

- ❌ Aftermarket actuators may look like a cheaper option, but cause errors, limp mode and expensive repairs.

❓ Frequently Asked Questions about Mercedes OM642 Actuators

1. Which ECU error codes indicate a faulty actuator?

The most common DTC codes are P123900, P2359 and P2510-1. These codes point to incorrect VNT position mapping, excessive boost pressure, or failed CAN programming of an aftermarket actuator.

2. How can I tell if the problem is with the turbo or the actuator?

If the engine loses power, enters limp mode, and shows boost pressure related errors, in most cases the actuator is the root cause rather than the turbo itself. Final confirmation comes from diagnostics and bench testing.

3. Is it better to install a new or remanufactured OEM actuator?

Both are correct solutions – a new OEM actuator offers factory precision, while a remanufactured and properly programmed OEM actuator restores the same factory specifications, verified on the test bench.

4. Why do aftermarket actuators cause problems?

Because they lack factory position maps and often lose data during CAN programming due to poor components. The result is unstable operation, ECU errors, and costly failures.

Contact Motorkov – Your Mercedes Turbo Experts

🔧 Do you have problems with your turbocharger or actuator?

👉 If your diagnostics show codes like P123900 or P2359, the actuator is likely the cause.

📍 Visit us at our workshop

📞 Call us: +381 64 1836269

🌐 Send us an inquiry via contact form

🎥 Check out our video: YouTube link